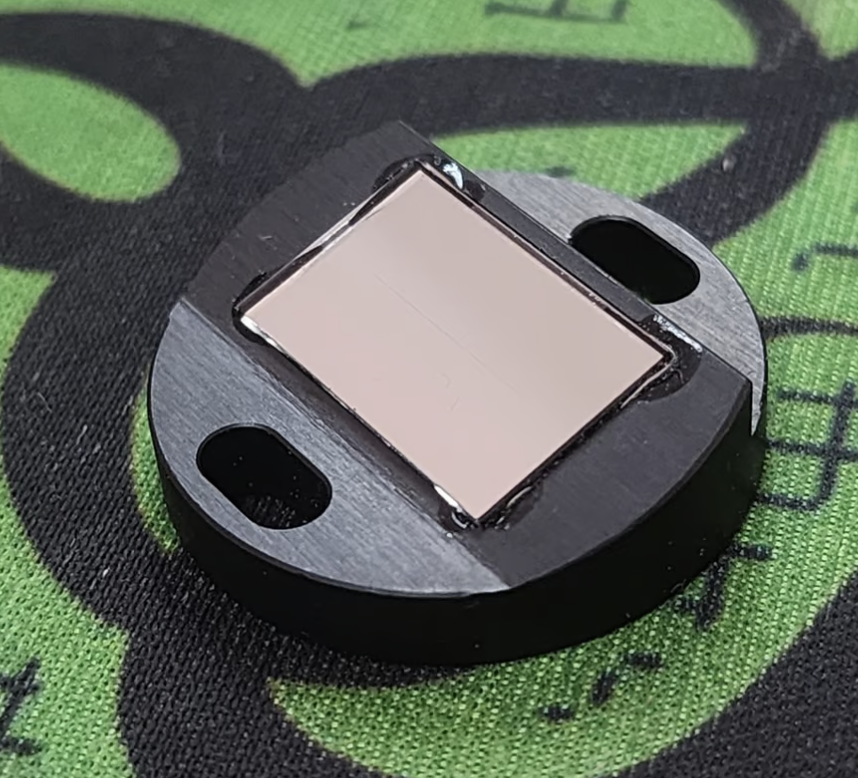

MLAstro 7micron, 7mm SHG slit

Our cutting-edge Quartz slit is the ultimate choice for any Spectroheliograph, delivering unmatched precision and durability for high-performance solar imaging.

$80.00

One of the most critical factors for slits used in an SHG (Spectroheliograph) is edge smoothness. Even the smallest edge defect or sub-micron dust particle on the slit can manifest as a vertical transverse line in the spectral spread, becoming highly visible despite the defect being extremely small—sometimes just a few percent of the slit width and sub-micron in size. This makes producing a high-quality slit an exceptionally challenging process.

To achieve the necessary precision, we utilize a lithography process, the same technology used in microchip manufacturing, to etch the slit on a specially coated surface. The result is an ultra-high-quality slit with unparalleled edge smoothness, ensuring minimal visual artifacts in your spectral data.

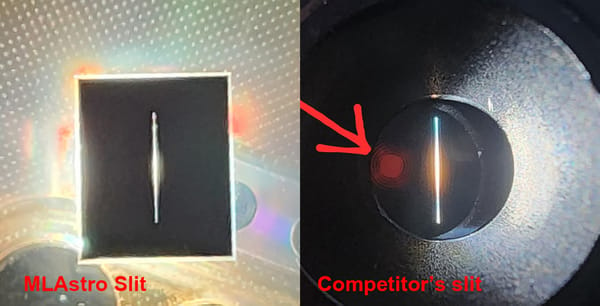

Our MLAstro slit is crafted with a special Quartz substrate and a unique coating process designed specifically for solar use. Unlike competitors' slits—repurposed from nighttime astronomy and made with lime-soda glass that expands and cracks under heat—our Quartz slit has a much lower expansion coefficient, making it highly resistant to the Sun's heat. The thick coating also provides a higher OD7 blocking rating, offering 100 times better blocking than the competitor's offer.

Our MLAstro Quartz slit is precision-engineered, with a surface figure polished to λ/4 or better. This stringent specification is essential to preserve the integrity of the wavefront passing through the slit, minimizing distortions that could degrade image sharpness and resolution. Unlike slits commonly used in spectrographs or laser systems, which often lack this level of precision, our design ensures optimal performance in solar imaging applications, where any deviation in wavefront accuracy can significantly impact the final image quality.

I have personally experienced a competitor's slit melting under a 60mm scope when no ERF was used.

We performed a burn test on our quartz substrate slit using a 15W, 915nm laser. During the test, the substrate glowed red hot but did not crack, thanks to the low thermal expansion of quartz. However, the coating sustained significant damage due to the high heat flux. The temperatures reached in this test are many times higher than those produced by the focused image of the Sun. This demonstrates the robustness of the quartz substrate under extreme conditions, though it also highlights the importance of proper handling to protect the coating.

I’ve been using MLAstro slit on a 4-inch (102mm) scope without ERF filters for extended periods without any issues.

Here’s a test demonstrating the impact of a higher blocking rating on solar imaging. You can see light from an LED shining through one of our competitor’s slit coatings, while our slit shows no light leak at all. This ensures maximum image contrast, giving you the clearest and most detailed solar images possible.

Disclaimer:

All of our slits are hand-tested under a microscope to ensure there are no significant defects along the edges. Any slit with a jagged edge is discarded. However, small amounts of dust and minor edge irregularities are an inevitable part of the manufacturing process. Our slits are created using the same lithography techniques used in microchip production. While companies like Intel invest billions in cleanroom environments, it's not feasible for us to perform all manufacturing, assembly, and packaging in such conditions.

We make every effort to avoid major edge defects, but minor imperfections can still occur. To set a clear standard (which is not commonly done in the industry), we've established the following guidelines for edge irregularities:

Multiple Small Defects: If a slit has more than one small edge defect (blocking less than 10% of the slit width) per 1mm of its length, it is considered defective. For example, in a 7mm slit, if there are more than 7 such defects, you are eligible for a replacement.

Large Defect: If there is a single large edge defect blocking more than 10% of the slit width, this qualifies the slit for replacement as well.

Edge defects are defined as obstructions that remain even after cleaning. We will provide a detailed guide on how to properly clean your slit in case dust is present.

For reference, a slit with a few transverse lines, as shown in the image, is not considered defective. Small edge defects do not impact image quality and can easily be corrected in post-processing software. In fact, some users find that minor imperfections can aid in focusing the camera and collimator more effectively.

A few important notes for the slit:

Usage without ERF: The slit is rated for use with telescopes up to 4" (102mm) in diameter without the need for an Energy Rejection Filter (ERF). However, if you have the option to use an ERF, we recommend it. Doing so will extend the life of the slit and provide better control over exposure times. For best results, consider using a subaperture narrowband filter as the ERF or a Herschel wedge to limit the heat flux. We do not recommend the use of ND filters for solar imaging, regardless of the brand or type, as they are not designed for this purpose and will degrade image quality.

Cleaning the slit: You can gently clean the upper side of the slit using lens tissue or a cotton swab, but do not touch the underside. The coated surface is extremely fragile and can be damaged easily. While small dust particles can be cleaned, oily fingerprints are highly damaging and cannot be removed effectively. If dust is present, use a bulb blower to clean it—do not blow on it with your mouth or use canned compressed air. If compressed air is necessary, ensure it comes from a filtered compressor.

Cleaning the underside: The dust on the underside of the slit can be cleaned carefully using a specific process that we will share later. Do not attempt to clean the slit without following this guide as improper cleaning will void your warranty, and we will be able to detect any damage caused

Mounting and Compatibility: The slit is mounted on a slanted mount and is fully compatible with Shelyaks optical kit, including use with the high-resolution Star'Ex configuration and the guide kit.

Spectral Resolution: The slit is narrower, which significantly increases spectral resolution. However, this also means that the image will be dimmer. As a result, for stellar spectroscopy application, longer exposure times may be needed for dimmer targets. For SHG applications, this increased resolution is desirable, and longer exposure is manageable, and does not pose significant issues.